Original Article written by Sarah Huffman

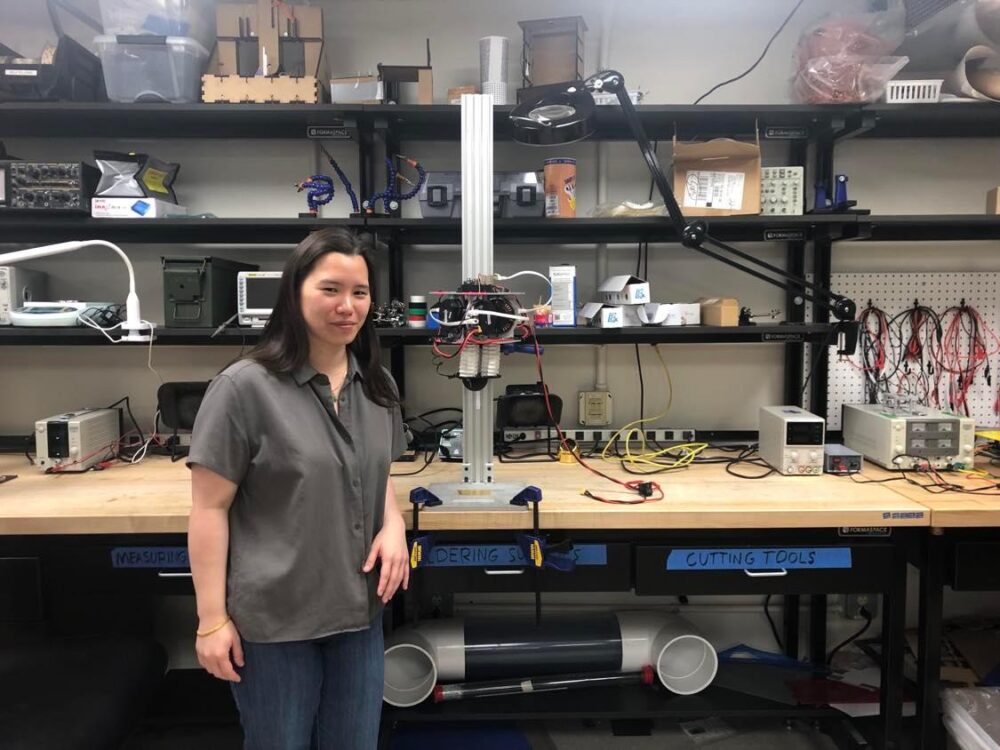

Cynthia Sung, head of the Sung Robotics Lab within Penn’s GRASP Lab, is especially interested in getting high school students into engineering. Self-folding origami robots, anyone?

Cynthia Sung thinks everyone should have access to robots.

She acknowledges robots can be expensive and difficult to design, which is why we don’t commonly see them in the average household. But she wants to change that through her research.

Sung runs the Sung Robotics Lab, which is part of the University of Pennsylvania’s General Robotics, Automation, Sensing & Perception (GRASP) Lab. Her lab is focused on making robots more accessible to the general public by researching quicker and cheaper ways to make robots.

“If we look to the future, technology is integrating more into everyday life,” she said. “Being able to customize your hardware, being able to have robots in your home to help you do everyday tasks, like your lawn, or play with your cat, or help you cook breakfast — [to do that] we need the ability to make designing and fabricating those robots easier, because otherwise, those technologies are never going to become more widespread.”

Sung’s robotics journey started when she joined a robotics team in high school. She went on to major in mechanical engineering in college and participated in a research project focused on rehabilitative robotics. She now has a Ph.D. in electrical engineering and computer science and has been working at Penn for six years.

Making robots accessible to high schoolers

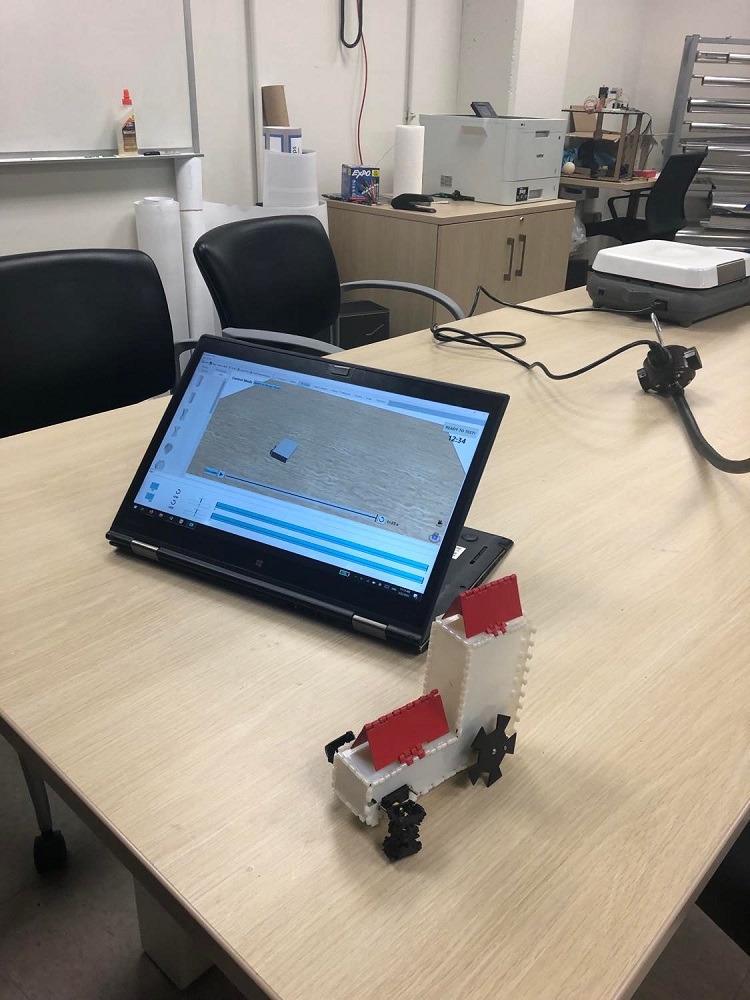

Part of this work includes developing software that would make robots easier to design, especially for non-engineers. Sung’s lab developed interactive software called Build-a-Bot, which allows a user to build a virtual robot, and the software will offer suggestions for what it could look like and how it will move. Based on the software’s predications, the user can change the design of the robot.

“What we’re really excited about with this software is that all of the designs that you create in the software are also connected to real fabrication files,” Sung said. “So once I’m happy with this design, I can also press print, and then it’ll print out files that I can send to a 3D printer, it’ll output a list of electronics that I need to buy to support the robot, and it’ll output some software that I can load onto the robot, so I can quickly assemble it.”

Once the user has all the pieces, Sung said, putting the robot together is usually pretty straightforward. Using the software, it’s possible to design and build a robot in an hour.

“Because the interface is very game-like, then the students really engage in the software and they enjoy tinkering with the robot and seeing how different design choices happen.”

-CYNTHIA SUNG SUNG ROBOTICS LAB

Her lab is now working with a psychologist at Oregon State University to study how students use the software differently from experts. That information will help make the software even more user friendly for non-experts.

Sung said her lab regularly works with high schools students, inviting them to play with the software and build their own robots. During these visits, the students are given challenge scenarios, such as specific tasks or terrains for their robots to traverse, to engage the students even more as they develop their robots.

She wants to see robots become cheaper, more accessible and and more customizable for students to physically engage in engineering, rather than just reading textbooks to learn about the subject: “Because the interface is very game-like, then the students really engage in the software and they enjoy tinkering with the robot and seeing how different design choices happen.”

Sung thinks with the freedom and flexibility that comes with building robots, eventually kids will be building robots the way they play with Legos.

Using origami in robotics

Sung describes herself and the people in her lab as being “folders,” meaning they have always enjoyed making things by folding materials. A lot of the work done in her lab is inspired by origami because folding structures is faster than 3D printing them.

For those who aren’t that into folding though, the lab is working on fabrication processes for self-folding structures. Yes, that means the paper folds itself into the desired shape. According to Ph.D. student Gabriel Unger, they sandwich a sheet of plastic between shrink wrap, and the structure folds after it’s heated up.

The ultimate goal for the Build-a-Bot software and the self-folding structures is that one day there could be robot-making kits for users to design robots virtually. Then, the pieces would be printed, and when the user gets the pieces, they could put them in the oven to self fold into their own robot.

The lab is also researching how durable origami and folded structures can be when applied to large-scale or dynamical systems. Postdoctoral researcher Wei-Shi Chen demonstrated a jumping robot that uses origami springs, explaining that origami materials are resilient, easy to fabricate and cheaper than other materials.

“This leg here has been hopping for thousands or tens of thousands of times, and it hasn’t shown any tear or any wear on [its] legs,” he said. “So this is resilient enough to do the stuff that normal robots can do, but because it’s semi-soft, semi-rigid, it’s also safe. If you bump into some people or something, it’s not going to hurt you at all. And so I think in perspective of safety, and fast prototyping, I think these are useful for us to replace a lot of the rigid components in dynamic robots.”

In the future, the lab will focus on how to bring all these techniques together.

“We’re interested in thinking about, what is the intersection between computation and design? How do we actually design with fabrication ideas in mind, and trying to bring all of these ideas together into fully integrated systems, is where we’re headed,” Sung said.