Original Article

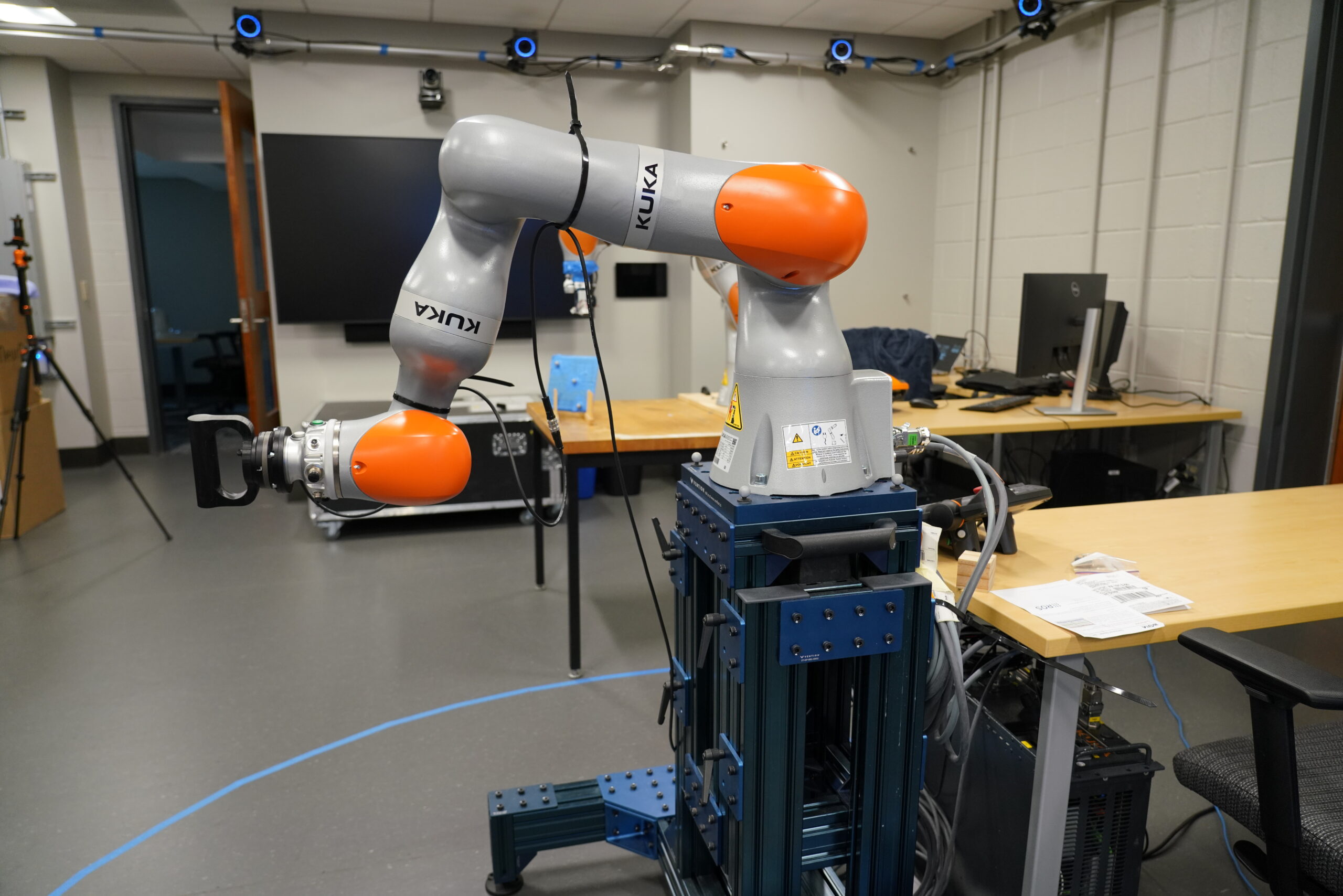

Industrial robots are automated machines for the use of manufacturing. Typically, these multipurpose machines consist of at least one reprogrammable robotic arm, or a manipulator, that operates on three axes or more. The widespread implementation of industrial robots in warehouses and on factory assembly lines can be credited to their ability to execute repetitive tasks at rapid speeds with high precision and no breaks.

Due to the nature of the work they perform, “industrial robots must be strong, fast and accurate,” Nadia Figueroa, a mechanical engineering and applied mechanics professor at the University of Pennsylvania, told Built In.

Typically, industrial robots are built to either handle extremely heavy loads (like when assembling a vehicle or a part of a plane), or to be extremely precise and fast (like when building electronics or packaging small products).

That makes most industrial robots “quite large and dangerous for humans,” Figueroa, who also advises at the GRASP Lab, said. “They’re often inside cages or behind fences so that humans remain out of harm’s way.”

Today, there are over 3.4 million industrial robots in the world, setting the global robot-to-human ratio in the manufacturing industry at one to 71. And, according to a McKinsey survey, industrial companies plan to invest one quarter of their capital into robotics over the next five years — a market that’s projected to hit $43 billion in revenue by 2027.

Continue the article